Solar Energy For A Changing World

Breweries And Distilleries

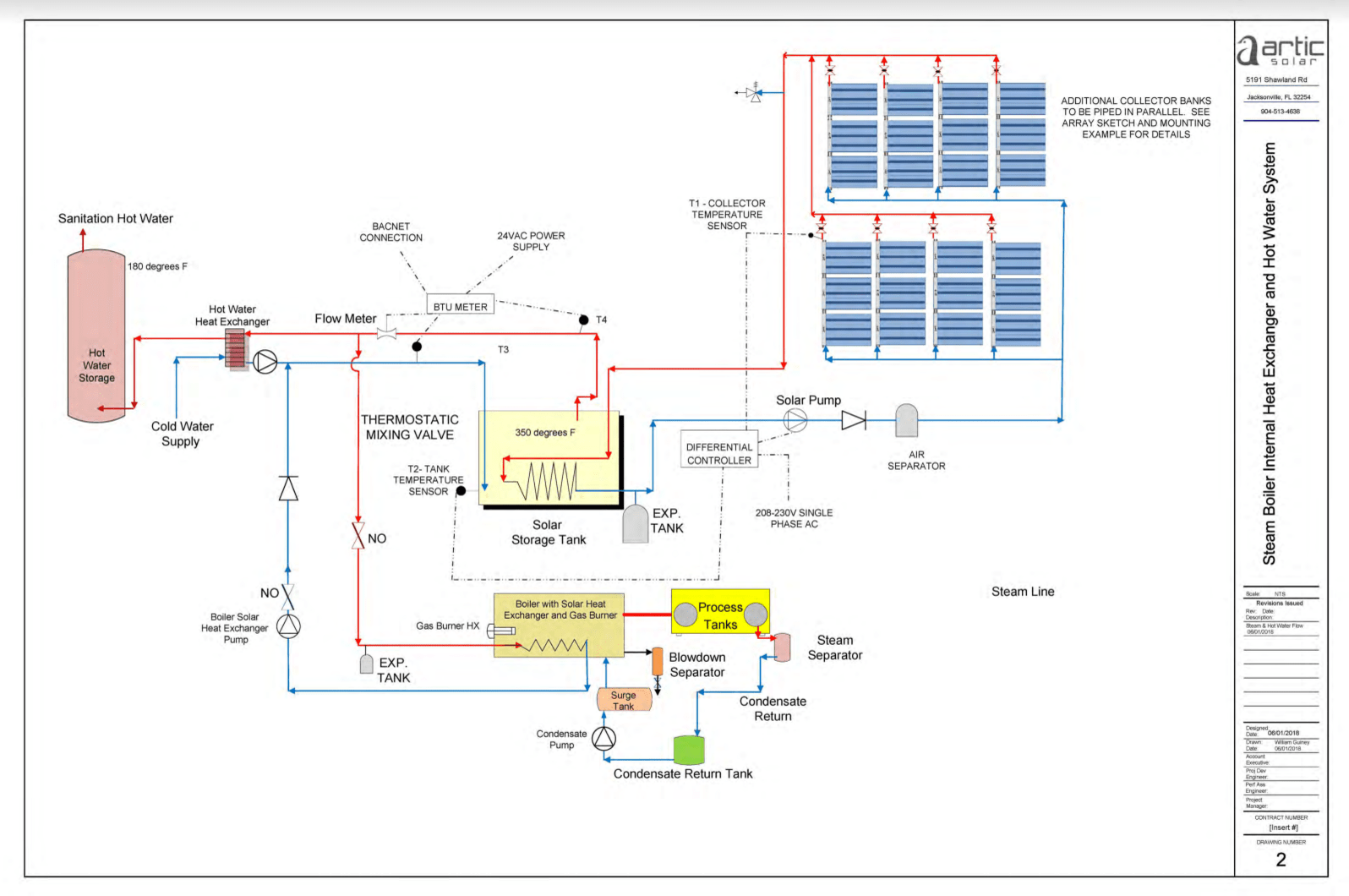

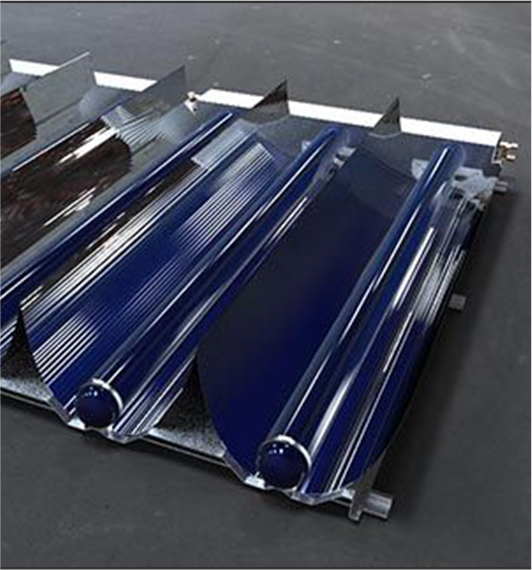

Solar thermal energy can be used for heating processes in all brewing and distillation processes, bottle washing machines, and pasteurizers or for cooling processes with absorption chillers. These are heat dependent processes.

The sun can be seen as the lowest cost of energy provider. In past years, many brewers and distillers have put great effort into energy conservation by installing photovoltaic (PV) to generate electricity and solar thermal energy collectors for their processes.

We’re with you every step of the way, including

System design – Engineering – Installation – Ongoing off-site monitoring